The history of Pumori Corporation began in 1990, when Pumori-Instrument was established to develop and manufacture clamping tools for modern metalworking CNC machine-tools. Its tools were to be able to replace analogous foreign-made products. That means that production has been one of Pumori’s main activities all the time from the very start.

Four member companies of the corporation are engaged in production at present.

Ural Tooling Systems Works — The only company in the Russian Federation and the post-Soviet space that designs and produces a wide range of clamping tools and boring systems.

Ural Tooling Systems Works — The only company in the Russian Federation and the post-Soviet space that designs and produces a wide range of clamping tools and boring systems.

The company has a modern, powerful production centre, a huge research and development potential, highly skilled workers and managers; it is experienced in the domestic and foreign markets.

The company keeps developing innovative products, some of which are unique.

It is certified to the ISO 9001:2008 quality system, and it delivers a high quality of workmanship in line with international standards.

PUMORI clamping tools are delivered not only to Russian, but also to foreign companies.

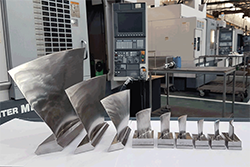

Pumori-Energy. Production of blades and vanes for steam and gas turbines. Blades and vanes are machined on Okuma’s (Japan) and C.B.Ferrari’s (Italy) 4 and 5 axis milling machining centres. Manufacturing quality control is performed with the usage of DEA (Italy) high-precision control and measuring machines.

Pumori-Energy. Production of blades and vanes for steam and gas turbines. Blades and vanes are machined on Okuma’s (Japan) and C.B.Ferrari’s (Italy) 4 and 5 axis milling machining centres. Manufacturing quality control is performed with the usage of DEA (Italy) high-precision control and measuring machines.

For many years the company has been completing orders of all Russian turbine makers, generating companies, service companies, and chemical production facilities. Pumori-Energy also fulfils many export orders for manufacture of blades and vanes of steam and gas turbines, and aircraft engines; accessory equipment for power stations, as well as spare parts for the repairs and modernization of the power equipment. The company often receives urgent orders and always executes them on time.

The quality management system is certified according to ISO 9001.

Quantity production of Pumori metal-machining centres.

The Genos TF‑12/500 CNC turning-milling centre has been designed after its Japanese analogue produced by the company since 2010 under a licence agreement with Okuma Corporation. Performs turning, milling, threading, drilling, and boring, and can be used in all mechanical engineering segments.

The components used in the new machine tool are manufactured mainly in Russia, or in friendly countries, while some items will be made by the company itself.

Joint assembly production of ACE-Pumori (Indian–Russian) vertical machining centres and lathes.

Joint assembly production of ACE-Pumori (Indian–Russian) vertical machining centres and lathes.

Milling centres can perform both roughing (incl. power milling) and finishing of surfaces requiring high precision; the parts to be machined can be of various materials, including hardened steel.

The lathe performs full-cycle lathe turning of rotary-body parts — both roughing using power cutting techniques and finishing of surfaces requiring high precision; the parts to be machined can be of various materials, including, among others, hardened steel.

The designers pay special attention to ergonomics. The quality of the equipment is attested. The machinery is recommended for any engineering application. The local content share is consistently growing.

Machine-tools produced by Pumori are in good demand and run well in a number of factories of various industry sectors.

Having an extensive background in deliveries and cooperation with leading global manufacturers of industrial automation, Pumori-North-West has developed its own product, Pumori Robotics.

It implements automation and robotization projects for machining production. Solutions offered include:

• robotic loading units,

• automated fitting complexes,

• blade/vane grinding and polishing applications,

• flexible manufacturing systems (FMS’s) and RoboFMS’s,

• individual projects.

Automation projects of any degree of complexity can be custom-designed and implemented. Using advanced software options coupled with hardware, the company’s specialists create high-performance solutions for high-variety productions.

Where to order?

Location

Not selected

Services and Products

Not selected

Brand

Not selected