-

Services and products

- Engineering

- Equipment

- Tooling

- Contract manufacture of complex parts

- Customer service

- Training

- Leasing

- Own production and export

- Home

- Services and Products

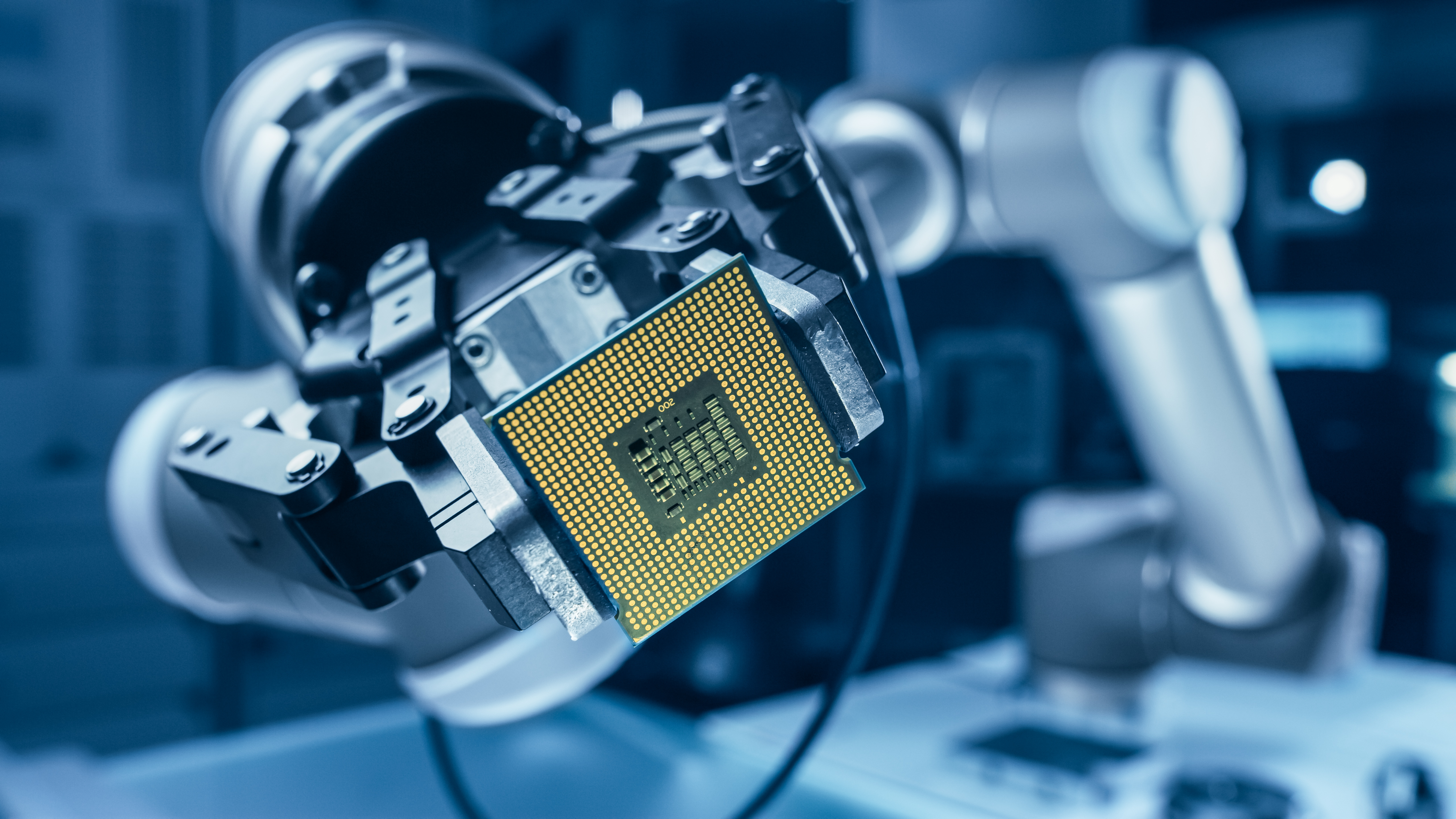

- Setup of an installation for unattended manufacture of parts of electrical appliances using flexible rapid-changing robotic cells

Setup of an installation for unattended manufacture of parts of electrical appliances using flexible rapid-changing robotic cells

A solution has been designed and implemented, with 4 robotic cells, each consisting of 1 machine and 1 industrial robot. Unattended manufacture process implemented for 20 part titles.

INFORMATION ABOUT THE PROJECT

- Customer:

Large industrial group producing on-board navigation, radiolocation, control, and safety systems for railway rolling stock - Provider: Pumori-Engineering Invest

Project aim

Setup of an installation for unattended manufacture, reduction of the manufacture labor hours.

Project stages

- Process design for machining of the parts

- Design of the robotic system

- Visualization of the system functioning

- Design and manufacture of tooling

- Development of NC programs for the machines

- Development of NC programs for the robot

- Assembly, setup, and start of the system

- Start-up

- Test manufacture

- Training of the customer’s staff

Project result

Increase in productivity by a factor of 3.5. Consistent workmanship achieved. The process enables 24×7 operation.