-

Services and products

- Engineering

- Equipment

- Tooling

- ☼ New brands

- Contract manufacture of complex parts

- Customer service

- Training

- Leasing

- Own production and export

- Home

- Services and Products

- Diesel engine production development project

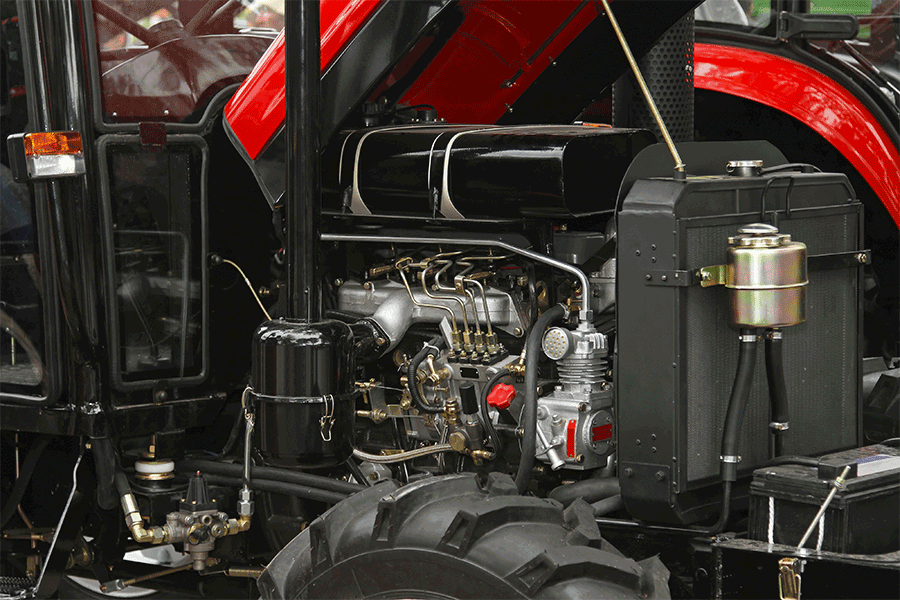

Diesel engine production development project

The project provides for an output increase from 3 to 10 thousand engines per year with the use of automation.

The process stages designed: machining, assembly, and testing.

INFORMATION ABOUT THE PROJECT:

- Customer:

One of Russia's largest industrial groups - Provider: Pumori-Engineering Invest

Project aim

Expansion of the existing production of small-sized universal diesel engines.

Project stages

Technological audit of the existing production

Technological audit of the existing production- Process design

- Consideration of contract manufacturing

- Development of specifications for the equipment to be purchased

- Evaluation of necessary equipment quantities and load factors

- Cutting, clamping and measuring tool requirements calculation

- Plant layout planning

- Planning of the production logistics structure

- Calculation of direct and indirect material consumption

- Calculation of energy consumption by the equipment being purchased

- Design of an optimum organization and staff structure and staff sizing

- Setup of the project implementation time schedule

- Project implementation costing

Project result

The project passed the management approval and the investors’ approval stages. The financing was obtained. The project has been accomplished in full.